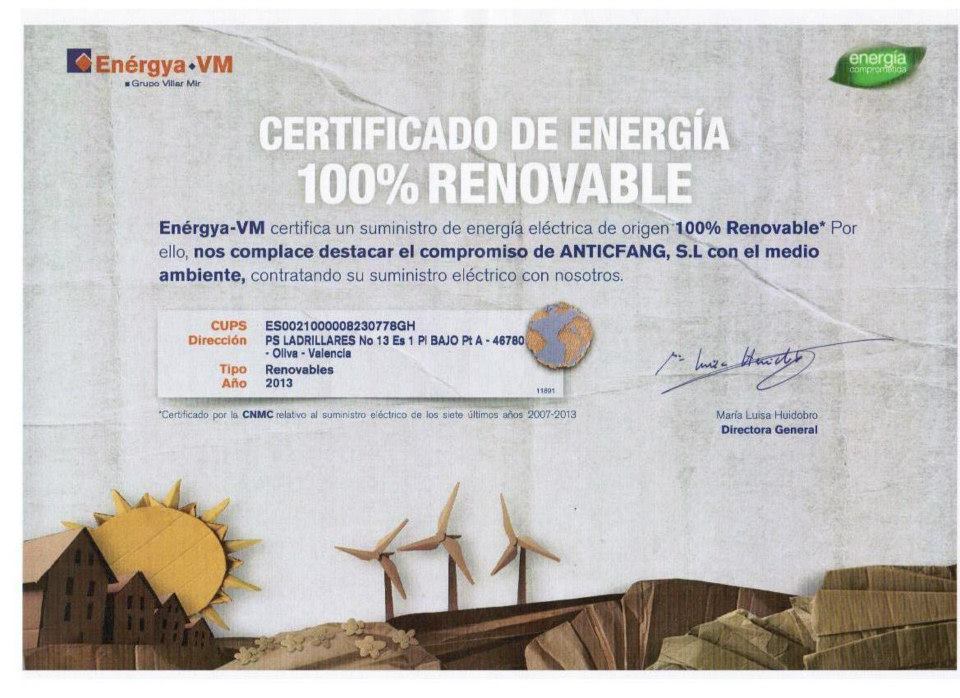

Artisan and Ecological Production

–

In Anticfang we keep the traditional methods in the manufacture of terracotta tiles. In a completely handmade process, we choose the best raw material, to which our artisans, give the form requested by our customers, to be later cooked in our ovens. The pieces are placed carefully inside the oven, following an established order so that all the pieces will cook correctly with a perfect result.

The cooking of the pieces is a process that lasts 10 days, the oven is heated up to 1000ºC. This temperature is maintained for two days to subsequently decrease until the end of the process. The cooking temperature of our ovens is unique, while the maximum cooking temperature in other ovens is 500ºC. At Anticfang we reach 1000ºC, achieving greater consistency, more resistance and therefore higher quality.

Our process is ecological, the fuel we use is biomass, composed of 100% crushed almond shell with little pollution. The consumption of the kiln is around 1,300 tons of biomass per year. This special fuel, allows a fundamental cooking for the process of destonificación of the product, endowing to the material of a range of special colors, that go, from subtle tones rosados until singular clear colors. Our kilns have a production capacity of 3,000 m2 / week.

By acquiring our products, we acquire the artisanal, quality, naturalness, ecological and beauty that our roots offer.

–